Fleet goals include Safety, Profitability, and Sustainability, among others.

PFT is focused on the following goals that support the above Fleet goals:

Fleet goals include Safety, Profitability, and Sustainability, among others.

PFT is focused on the following goals that support the above Fleet goals:

Safety is enhanced by using the component predictors to alert the staff when components near End-of-Life (EoL). Also, driver behavior data is available to promote safe driving. Both of these have fines and other penalties that also affect the Fleet’s profitability.

Profitability is affected by increasing revenues and decreasing costs. As long as the Fleet has more customers, revenues can be increased by keeping assets out of the Out of Service (OoS) category and Drivers’ loyalty high. The predictors can help minimize OoS status of assets and drivers less frustrated by having to wait (not accumulating hauls) for the asset to be returned to service.

Increased engine efficiency by using EP and EA to spot lower engine performance and increasing fuel costs and recommending corrective action early on cuts operational expenses.

Reduced environmental impacts from well maintained engines, tires, etc. reduces fuel costs and also reduces regulated emissions. These results make the public more receptive to trucking, reduce fines from violating regulations and also decrease your operational costs.

Increased asset useful life allows you to lower investment costs or enable more value on trading with well-maintained vehicles and trailers when you decide to cull your Fleet.

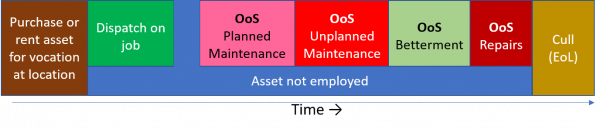

The life of a Vehicle/Trailer consists of the indicated states from ‘purchase’ to ‘cull’. The ‘states’ between purchase and cull are not sequential, but those near the right tend to ‘grow’ as the age of an asset increases.

The revenue generation consists of ‘dispatch on a job’. Betterments can decrease costs and increase asset value.

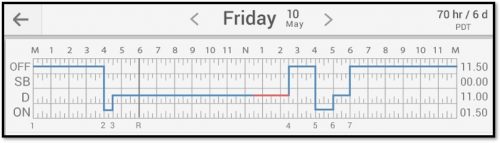

‘Asset not employed’ is estimated for single-driver rigs so ‘nights’ and 1 day a weekend are idle.

Buy the most appropriate equipment: EA provides data to help recommend features and models for purchase based on the requirements of your customer base & highway network.

Keep your assets dispatched on-the-job (minimize OoS) to increase revenue.

Better your operation with new technologies that will save you money! EA has a module to help evaluate new technologies available as Betterments to measure the change expected by implementation on your fleet.

Cull the least productive (including maintenance costs) assets based on EA data.

Models connect status of Assets with ‘as built’ data, usage data, intervening inspection data, environmental factors, PM, repair and betterments data. The models identify important correlations to help explain deterioration and recovery factors. These correlations are also used in conjunction with asset usage rates to predict ‘End-of-Life’ (EoL) dates for components.

Data is expensive to keep timely, accurate, and complete.

The predictors recalculate the EoL for monitored components. Inspection and repair data adjust the predictors to tailor the models to the experience of the vehicle.

Items in italics are not yet completed.