Some of the business processes that have been improved using these types of analytics are:

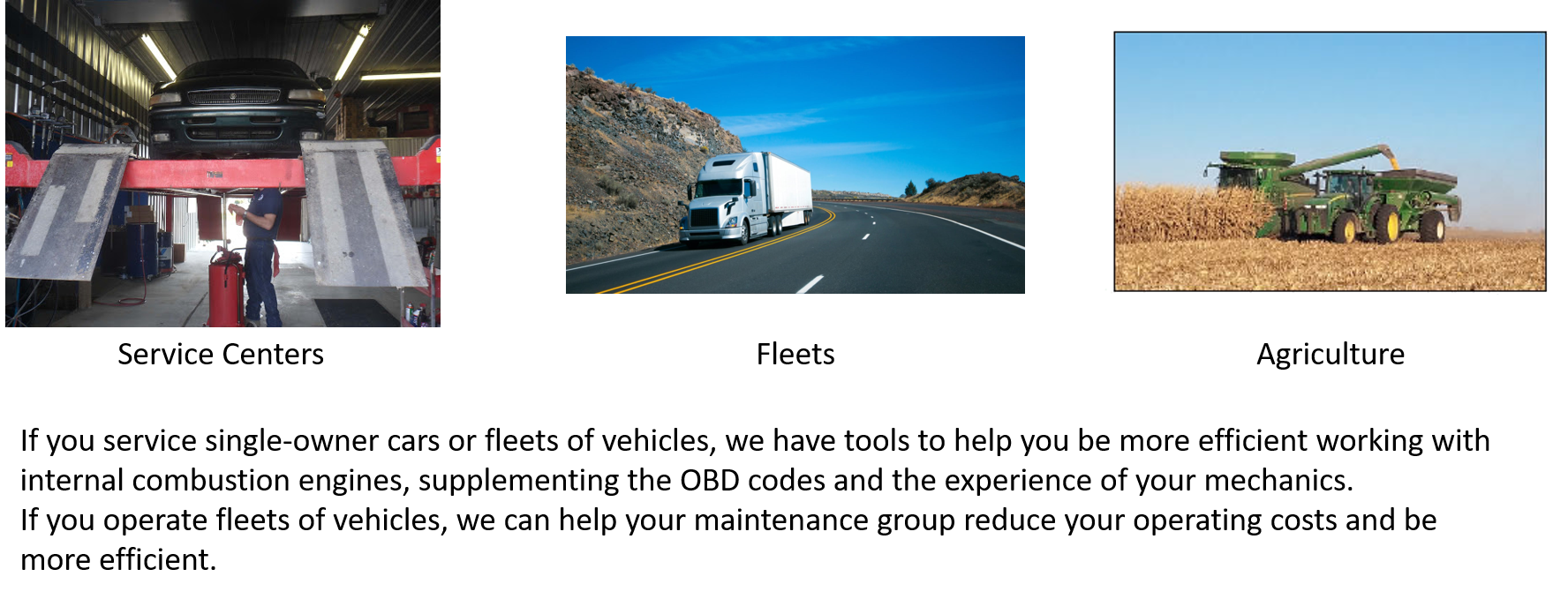

- Fleet culling with ranking assets by performance and cost-of-Ownership

- New technology evaluation based on testing in your fleet

- Driver retention and improvement with Driver Performance Analysis incorporating vehicle condition

- Improve fuel economy by detecting quantified asset performance declines for earlier corrective action.

- Reduced time operating assets with performance issues – identify emerging problems quicker, reducing hauling costs & reducing risk of urgent substitution of equipment & drivers

- More satisfied drivers with fewer trip disruptions and delays

- Reduced diagnostic time, diagnostics accurate more often means less time OOS

- Fewer fines/OOS tags for equipment out of compliance; lower insurance costs

- Improved customer satisfaction from fewer delayed deliveries

- PM scheduling and parts inventories based on End-of-Life calculations (reduced asset downtime, fewer on-road repairs, more effective inventory investments and space usage)